Literature and Knowledge Center

In-depth information on Kingsbury products, technologies and applications.

Tilting Pad Temperature Pattern Variations in Babbitted Fluid Film Bearings

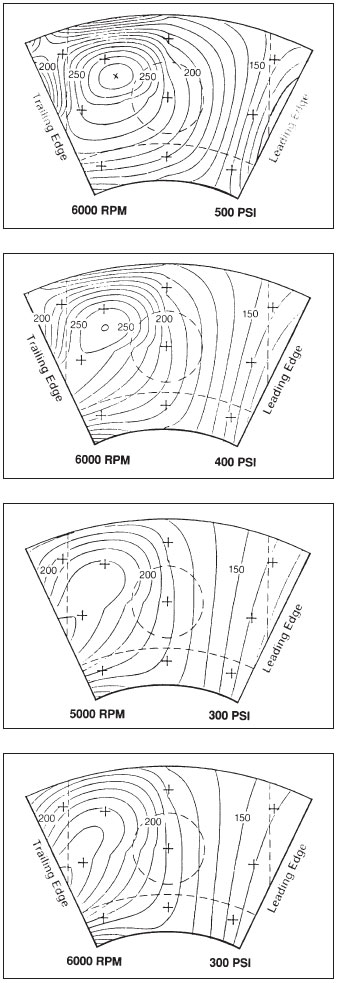

A temperature sensor mounted at the 75/75 position can provide the critical tilting pad (also called a bearing shoe) temperature for that one, fixed location, but cannot indicate the temperature pattern over the entire pad surface. In order to demonstrate the localized nature of the critical temperature region, we rely on isotherms (lines of constant temperature) based upon an array of 9 thermocouples evenly distributed across the pad surface, plus a tenth thermocouple at the 75/75 location. The sensors are embedded in the babbitt material, approximately 0.03" (0.76 mm) below the pad working surface. Values from all ten thermocouples are curve-fit in the circumferential and radial directions to obtain intermediate temperature values at other locations on the pad. These combined measured and intermediate temperatures are plotted as isotherms in the accompanying illustrations.

The isotherms shown here demonstrate the changing temperature patterns which develop under various operating conditions.

The isotherms shown here demonstrate the changing temperature patterns which develop under various operating conditions.

For example:

- Thermal conduction, supply groove mixing, and hot oil carryover conspire to raise leading edge temperatures as high as 140°F (60°C) for standard oil flow rates, despite the cool 115°F (46°C) oil supply temperature.

- Raising the oil flow rate reduces leading edge temperatures by only a few degrees.

- Temperature parameters

- Measured temperatures will vary according to:

- Shaft speed

- Load

- Oil flow rate

- Oil viscosity

- Pad design

- Type of pad metal (thermal conductivity)

- Depth of installed sensor

Moving across the pad from the leading edge to center pivot, the isotherms are widely and uniformly spaced in a near-radial pattern. What is the cause? Relatively thick oil film and minimal deflection of the pad.

Beyond the pad's center, the thermal gradient becomes much steeper and more indicative of the actual oil film thickness.

Sometimes, thermal crowning and load distortions produce a distinct hot spot such as that shown at 6000 RPM, 500 PSI (3.45 MPa), with a temperature above 270°F (132°C).

Important: In a region of high oil film pressure, such a critical temperature is much more dangerous than a hot spot developing at a trailing edge for 6000 RPM, 300 PSI (2.07 Mpa), where the parabolic pressure distribution falls to zero.

By varying some of the factors which influence pad temperature, we can evaluate overall bearing temperature performance based upon that change and prevent problems like premature babbitt bearing failure. For example, we have been able to measure the effects of reducing pad thickness and using a smaller pad support in our bearings.