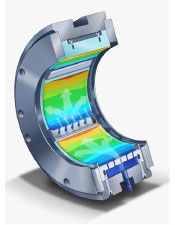

High speed turbomachinery such as centrifugal compressors and turbines can place enormous stresses on bearings. In 1985, Kingsbury pioneered the development and commercialization of its Leading Edge Groove (LEG®) thrust and journal bearings which were developed in direct response to the need for increasingly faster speed ranges and accommodating higher load capacities for these applications.

Leading Edge Groove bearing technology now leads the industry

For new applications as well as for retrofits, LEG® thrust and journal bearings provide the following benefits

- Lower friction power loss for increased overall machine efficiency.

- Lower operating temperature and increased load capacity.

- Lower oil flow requirements for smaller lubricating oil systems and lower capital costs.

- Ability to optimize for maximum load capacity or to minimize power loss.

For nearly 40 years, Kingsbury’s LEG® thrust and journal bearings have been in successful operation in thousands of compressors and other high-speed turbomachinery applications, saving users energy, reducing oil flow, and increasing capacity using smaller machines.

Enter the BPG® Journal bearing for even greater machine efficiency

More recently, Kingsbury developed an enhanced variation of the Leading Edge Groove called Between Pad Groove (BPG®). This new journal bearing is the ideal choice for high speed, high load applications such as gearboxes as well as other turbomachinery and power generation equipment. The unique features of this design allow machines to operate under loads and speeds that cannot be achieved with conventional flooded journal bearings, while also permitting shaft rotation in both directions when bi-directional rotation is required.

- BPG® journal bearings direct lubrication using feed bars between pads to introduce cool oil

- BPG's lower oil flow rate results in significantly reduced power losses

- Unlike the LEG® bearing, BPG® is designed for bi-directional shaft rotation

Kingsbury’s directed lubrication bearing enjoy a well-established reputation in the oil & gas and petrochemical industries through installation in literally thousands of compressors and other turbomachinery applications, both as retrofits as well as new machines. Ask us to evaluate your application to see if we can offer you better results with a Kingsbury LEG® or BPG® in your turbomachinery designs.

Kingsbury’s Bearing Selection App will get you in the right ballpark, but to learn more about which bearing type is best for your machine design, we encourage you to contact a Kingsbury application engineer.

Bearings for Oil & Gas Equipment

Petroleum extraction, refining, transportation, and storage utilizes a multitude of pumps, compressors, turbines, blowers, expanders, and other industrial equipment. The extreme pressure on process availability and production requires the most reliable and efficient equipment available. Kingsbury is the number one supplier of fluid-film babbitted bearings to this critical and extremely demanding application market.

High Speed, High Efficiency

Kingsbury pioneered the directed lube thrust bearing in the early 1990s, allowing compressors to operate at higher speeds with better efficiency and process throughput. For original designs, or performance-improving drop-in retrofits, ask Kingsbury about reducing oil flows, increasing load capacity, all while reducing operating temperatures, with Leading Edge Groove (LEG) thrust bearings.

Maximizing Performance

Kingsbury not only invented the Leading Edge Groove (LEG) directed lube thrust and journal bearing. Over the past fifteen years, Kingsbury's Research & Development has tested various design modifications to the basic LEG technology which further expand the operating range of our bearings, while creating an expert set of predictive tools for guaranteeing machine stability under this demanding conditions.

Off Shore Oil Platform

Oil Platforms are one of the most demanding locations for rotating equipment. Space is at a premium; unscheduled down-time can cost hundreds of thousands or even millions of dollars. Kingsbury offers bearings which support the most power-dense applications in the industry, and the assurance and reliability of Kingsbury bearings allow you to "forget about your bearings".

Axial Compressor "PJ" Bearings

The high-speed equipment used in the O&G industry requires closer monitoring of bearing performance parameters, most notably temperature. Kingsbury is proud of the accuracy of its pad temperature predictions and has the expertise you need to help reduce operating temperatures, if necessary, with alternate shoe materials, revised pad geometry, and modified lubrication arrangements.

Offset Pivot Thrust Pads

Kingsbury's Repair & Service Division will repair your damaged bearings of any make and model. We are aware of how critical it is to keep your units running. Kingsbury stocks a full line of its standard parts for quick replacement. If your damaged bearings are non-standard, or non-Kingsbury, our Repair & Service Division can normally repair or replace within two weeks, and for emergencies will offer round-the-clock assistance if you need it.

Gas Compressor

Kingsbury provides thrust and journal bearings to the biggest names in the rotating equipment industry.

Turbo-Expander

High-speed, high-load applications such as turbo-expanders, place high demand on bearings. Bearings sizing and capabilities are limited by load (which affects the operational oil film thickness) and the bearing pad temperature (mechanical limit of the material). Every machine and every process can vary. Kingsbury's selection tools and experience allow us to provide you with the best bearing for your specific machine and the specific operating parameters of your process.

Pump Journal

Pumps, blowers, and other plant support equipment are just as important to your plant's success as your process equipment. Kingsbury has a full line of standard, cost-efficient bearings and inventory to support all of your support and auxiliary equipment.

Offset Pivot Thrust Pads

It is common fluid-film bearing knowledge that offset-pivot thrust bearings carry higher loads at lower operating temperatures than center-pivot designs. However, the optimal offset varies considerably with pad geometry, load, and speed. Kingsbury has the empirical test data and theoretical codes which help us to select the optimal offset for your critical-application bearing.

Pipeline Multi-Stage Pump

Large and multi-stage pumps often use Kingsbury J-type flooded and LEG-type directed-lube thrust bearings. LEG bearings are typically used in high-speed, high-load applications, but LEG's are selected by some OEMs for lower speed equipment, such as pumps, because they require only half of the oil needed for flooded designs, therefore reducing the size and capacity requirements of expensive lube systems.

Journal Bearing

Kingsbury manufactures and supplies plain journal bearings as well as tilting-pad. Plain bearings can be supplied with multiple geometries, including plain cylindrical, elliptical, off-set halves, multi-lobe, pressure-dam, and others, in a variety of materials including steel, bronze, bearium-bronze, and special composite materials and coatings.