How to Select the Best Fluid Film Journal Bearing for Your Application

Kingsbury offers three types of fluid-film journal bearing technologies to balance your performance and economic goals perfectly.

PJ Tilting Pad Flooded Bearing

Features & Benefits:

- End shields with or without floating rings ensure that the inside of the bearing is flooded with oil.

- The oil flow rate can be regulated by orifices in the annulus machined into the outside of the aligning ring or in the discharge through sealing gaps and outlet holes.

- The flooded type of lubrication has advantages in the event of an unexpected interruption in the oil supply or vibration problems that could arise due oil starvation seen with other lubrication types.

Maximum Speed: 70 m/sec (13,790 ft/min)

Applications: Medium-speed steam and gas turbines, gear-boxes, compressors, pumps and pulp refiners.

Request Info or a Quote

LEG® Tilting Pad Directed Lube Bearing

Features & Benefits:

- Kingsbury’s patented LEG® journal bearings have directed lubrication type using grooves incorporated at the leading edge of the pads.

- In LEG® bearings, the fresh oil goes straight into the lubrication gap. As a result, the oil requirement is reduced to almost the hydrodynamic oil flow.

- LEG® bearings are usually designed with a pad pivot offset 60% of its effective length, enhancing the load capacity at higher operating speeds. This bearing is meant for unidirectional shaft rotation.

- LEG® bearings can substantially reduce the oil flow rate, power losses, operating temperatures, all the while increasing the load capacity.

Maximum Speed: 110 m/sec (21,670 ft/min)

Applications: High-speed steam and gas turbines, gearboxes, compressors, pumps and pulp refiners.

Request Info or a Quote

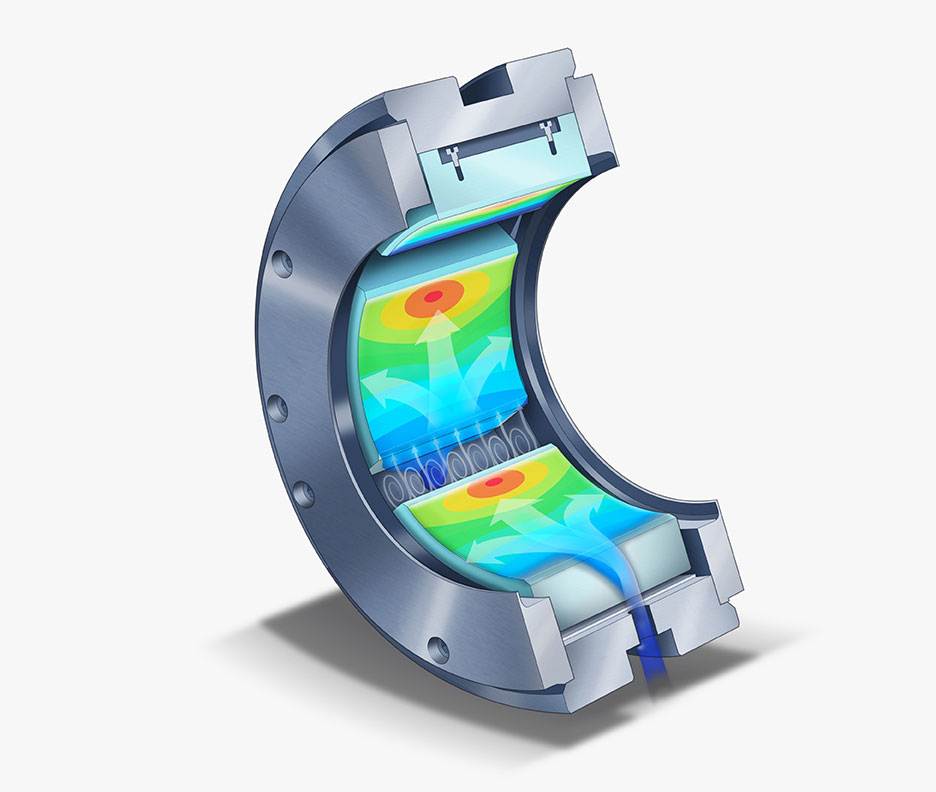

BPG® Tilting Pad Directed Lube Bearing

Features & Benefits:

- BPG® journal bearings have directed lubrication, using feed bars placed between the pads to introduce cool oil from the groove directly into the load-carrying film.

- The proprietary shape of the oil feed bar allows reductions of the oil flow rate and enhances the cooling effect in the leading-edge area of the pad.

- The lower oil flow rate in the BPG® bearing results in significantly reduced power losses.

- The BPG® provides very good static as well as dynamic properties in turbomachinery applications.

- The BPG® design has a positive influence on the temperature profile in the laminar-turbulence transition regime.

- Unlike the LEG bearing, the BPG is designed for bi-directional shaft rotation.

Maximum Speed: 120 m/sec (23,640 ft/min)

Applications: High-speed steam and gas turbines, gearboxes, compressors, pumps and pulp refiners.

Request Info or a Quote

We'll help you choose:

- A New Journal Bearing PDF: Complete Kingsbury Journal Bearings: Tilting Pad, Flooded and Directed Lube Types with all details on models, features & benefits, applications, engineering background, and dimensions.

- Bearing Selection Tool A step by step selection process that leads engineers to the model they need.