LEG Journal Bearings

Leading edge groove technology boosts machine performance, reliability and efficiency.

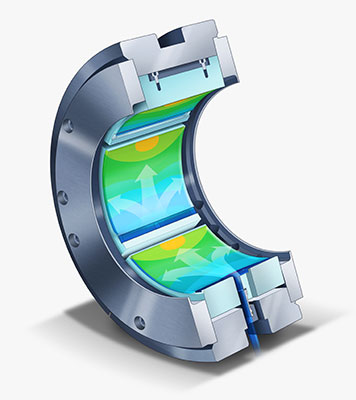

Each standard LEG pivoted shoe journal bearing consists of five journal shoes supported in a precisely machined aligning ring. Smaller journal shoe bodies are manufactured from heat-treated 4100 class alloy steel. If the bearing bore is over 10” [250 mm], the shoes incorporate heat-treated 4100 class alloy steel pivot inserts. The back of the journal shoe or pivot insert is contoured differently in both the circumferential and axial directions so the shoe can tilt and pivot to develop an optimum oil film and self-align to the journal.

Kingsbury LEG bearing shoes are designed with offset pivots, 60% of the effective length of the shoe.

High-tin babbitt is centrifugally cast, metallurgically bonded, then precisely machined to create the bearing surface. Proprietary manufacturing processes provide a uniform babbitt thickness across each journal shoe, while tight design tolerances permit interchangeability of shoes, both within a single bearing and between different bearings of the same size.

The combination of hardened alloy steel and moderate Hertzian stresses allows Kingsbury pivoted shoe journal bearings to be used in high shock load or vibration applications without damaging the pivot contact areas.

Aligning Ring

The aligning ring, manufactured from heat treated 4100 class alloy steel, is axially split to allow easy assembly of the bearing around the shaft. Both halves are doweled for positive realignment and secured with socket head cap screws, while a hardened steel dowel on the cylindrical outside diameter prevents rotation of the bearing assembly in the housing.

An oil distribution annulus is machined into the outside of the aligning ring, and feed tubes direct cool oil from the annulus to the groove at the leading edge of each shoe.

Shoe Retention

The shoe retaining plates are manufactured from tempered aluminum plate. They are axially split and precision bored to regulate oil discharge from the bearing assembly. Locating pins at the ends of each journal shoe match corresponding holes in the retaining plates to provide accurate circumferential positioning, and to retain shoes when the bearing assembly is split for installation or inspection.

Oil Feed Tube

The oil feed tube, connecting the base ring and pad, is designed so that the pad is free to pivot. This not only allows freedom of movement in the pad, but also eliminates the possibility of leakage by directing the oil directly to the pad face.

The oil feed tube, connecting the base ring and pad, is designed so that the pad is free to pivot. This not only allows freedom of movement in the pad, but also eliminates the possibility of leakage by directing the oil directly to the pad face.

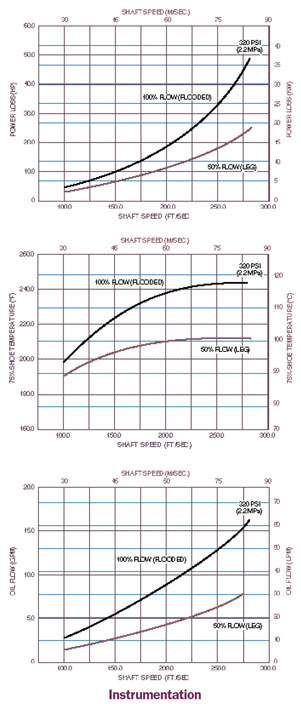

LEG Bearings Outperform Flooded and Other Directed Lube Types

Kingsbury's LEG bearing design has proven itself through exhaustive testing and years of trouble-free operation to represent the ultimate in directed lubrication technology. Yet the design concept is remarkably simple.

The bearing shoes and aligning ring are constructed so that cool undiluted inlet oil flows from the leading edge groove in the bearing shoe directly into the oil film. The cool oil in the oil film wedge insulates the babbitt face from the hot oil carryover that adheres to the shaft.

Because of these features, LEG journal bearings can:

- Reduce operating temperatures at the 75% location by 6 to 17°C, depending on load and speed.

- Provide a load capacity increase of 15% to 35%.

- Operate at 50% lower oil flow rates with an accompanying reduction in power losses of 30% to 50% depending on speed.

Power loss is lower than in flooded and spray feed bearings due to the elimination of parasitic losses. The flow of cool oil over the leading edge lowers shoe surface temperatures, increasing the LEG bearing's capacity. The resulting performance improvements are shown in these graphs.