Bearing Services

A full range of aftermarket services for total customer support.

Kingsbury Rebabbitting Services

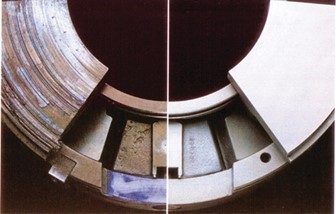

The babbitt on hydrodynamic bearings is a layer of sacrificial

material covering the working face of the bearing. It is designed to be soft

enough that contaminants can embed in it, thereby protecting the shaft or

thrust runner. The babbitt material is typically composed of an alloy of tin,

though a variety of metals and even some high temperature plastics can be used.

If any of the babbitt surfaces of a bearing display wear,

burning, blistering, pitting, lubricant degradation, or any other unexpected

appearance, bring it to the attention of Kingsbury bearing experts, as these

signs and symptoms are useful in determining more than just when and whether

the babbitt is in need of repair or replacement. The Kingsbury experts can advise operators on

whether an issue is user serviceable or requires professional service, and

whether the symptoms point to larger underlying problems with the overall

mechanical system.

For more Babbitt diagnostics see Section II of The General Guide to the Principles, Operation and Troubleshooting of Hydrodynamic Bearings. It contains illustrations and information for identifying and troubleshooting the many issues hydrodynamic bearings are subjected to, and how to address them.

Kingsbury is the industry leader in rebabbitting of turbine bearings, babbitt bearing repair, and rebabbitting services. Please reach out to our outstanding service department.

Phone: +1-215-956-0565

Email Repair@Kingsbury.com (Repairs & Field Service).

Contact Kingsbury

Resources

Preventing Electrical Pitting Damage

Preventing Electrical Pitting Damage

Spring Bed Bearing Retrofit

Spring Bed Bearing Retrofit

Turbulent Transition in Tilting Pad Journal Bearings

Turbulent Transition in Tilting Pad Journal Bearings

Diagnosing Overheated Bearings

Diagnosing Overheated Bearings

Vibration Issues

Vibration Issues