Bearing Services

A full range of aftermarket services for total customer support.

Engineering Support

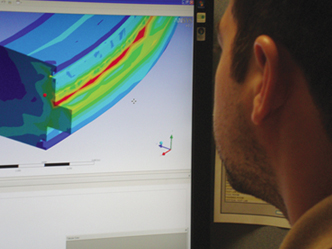

Kingsbury engineers are known for their success

in developing innovative problem-solving technologies that reduce power losses, increase operating speeds, and

deliver optimal efficiency. In fact, no one else rivals our expertise in application engineering and design. We

start by providing a thorough technical review of your needs and follow up with a tailored solution to ensure that

you get the best overall performance from your equipment. This applies not only to new units, but also to system

upgrades and retrofits.

Kingsbury engineers are known for their success

in developing innovative problem-solving technologies that reduce power losses, increase operating speeds, and

deliver optimal efficiency. In fact, no one else rivals our expertise in application engineering and design. We

start by providing a thorough technical review of your needs and follow up with a tailored solution to ensure that

you get the best overall performance from your equipment. This applies not only to new units, but also to system

upgrades and retrofits.

Kingsbury operates two production facilities for pre-engineered and custom bearings – one at our headquarters in

Philadelphia, PA and the other in Oshkosh, WI. Our ISO 9001-2008 certified production plants feature

state-of-the-art CNC and robotic manufacturing systems to ensure that your bearings meet your precise

specifications.

Our experienced field engineers can offer start-up assistance to ensure a trouble-free bearing installation.

They'll also provide on-site analysis and service to diagnose and correct problems in existing installations,

maximize bearing performance, and improve overall application efficiency.

Contact Kingsbury's Engineering team at engineering@kingsbury.com.

Expert Phone and Field Support

Our Field Service and Engineering team can answer your bearing questions over the phone or via

e-mail, depending on your preference.

Our Field Service and Engineering team can answer your bearing questions over the phone or via

e-mail, depending on your preference.

Kingsbury is proud to have the largest staff of Field Service, Design, and Research & Development Engineers in

the fluid-film bearing industry. It is this expertise that makes us invaluable to our customers.

For times when you need expert assistance in the field, contact our office and we will send out a field service

technician.

Our Field Services Include:

- Troubleshooting, inspection, field repairs

- Bearing installation and start-up support, including alignment

- Teardown and disassembly support

- Babbitt Bearing Repair, scraping, and rebabbitting

- Training / Seminars

To inquire about Kingsbury training, call us at +1-215-956-0565 or email Expert@kingsbury.com.

Contact Kingsbury

Resources

Preventing Electrical Pitting Damage

Preventing Electrical Pitting Damage

Spring Bed Bearing Retrofit

Spring Bed Bearing Retrofit

Turbulent Transition in Tilting Pad Journal Bearings

Turbulent Transition in Tilting Pad Journal Bearings

Diagnosing Overheated Bearings

Diagnosing Overheated Bearings

Vibration Issues

Vibration Issues