Gas and Steam Turbines

Kingsbury has supplied thousands of bearings for high speed/high load gas and steam turbine applications.

History of Modern Gas and Steam Turbine Bearing Development

In the early 1980s, gas turbine bearing and steam turbine applications began pushing the safe operating limits of flooded tilting pad hydrodynamic bearings. Shaft speeds and loads had increased to the point that bearing surface temperatures and associated power losses were of concern in the design of larger, faster, more efficient turbines.

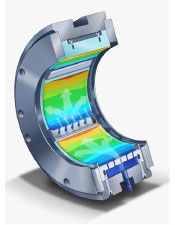

In response to the demands of our market, Kingsbury developed the Leading Edge Groove (LEG®) lubrication technology for both thrust and journal bearing applications. This design provides superior bearing performance while simultaneously reducing oil flow requirements, which translates into higher turbine efficiency.

The Advantages of LEG® Technology vs Flooded Bearings

- Reduces operating temperatures by 5° to 20° C, depending on shaft speed

- Increases load capacity by 15% - 20%, reducing required bearing size

- Lowers oil flow by 50%, allowing for reduced lube system demand

- Improves efficiency, with a 45% reduction in friction losses

The applications and data demonstrate that LEG® technology is a cost effective and reliable method of lubrication that improves efficiency, lowers capital costs, and adds value to machinery.

Enter the BPG® Journal bearing for even greater machine efficiency

More recently, a new addition has joined the directed-lubrication family of Kingsbury journal bearings, the Between Pad Grooves (BPG®), improving machine performance even more:

- BPG® journal bearings direct lubrication using feed bars between pads to introduce cool oil

- BPG's lower oil flow rate results in significantly reduced power losses

- Unlike the LEG® bearing, BPG® can be designed for bi-directional shaft rotation when required

Kingsbury’s Bearing Selection App will get you in the right ballpark, but to learn more about which bearing type is best for your application, we encourage you to contact a Kingsbury application engineer.

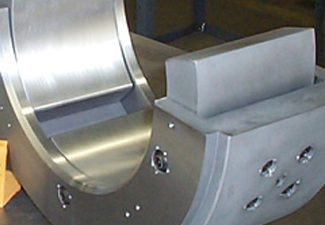

Kingsbury Design and Manufacturing Advantages

Kingsbury uses laboratory test data as well as real-time application data in order to provide bearing performance calculations that are the most accurate in the industry. Kingsbury's ability to predict operating performance allows us to select the right bearing for every application, and to provide the right fix or upgrade for any problems you are experiencing with your current bearings.

There are other advantages to Kingsbury bearings: we maintain a large inventory of standard parts for gas and steam turbine installations. We offer ultrasonic and dye penetrant testing on new items and perform 100% inspection of bond integrity on repaired thrust and journal bearings. Finally, Kingsbury can provide instrumentation to allow you to monitor bearing performance, including thermocouples, RTDs, bayonet probes, load cells, axial displacement probes and vibration sensors.

Kingsbury’s directed lubrication bearing enjoy a well-established reputation in the power generation industry through installation in literally thousands of gas or steam turbines, both as retrofits as well as new machines. Ask us to evaluate your application to see if we can offer you better results with a Kingsbury LEG® or BPG® in your turbomachinery designs.

For Gas and Steam Turbine Bearings Repair, Retrofit, or Replacement, visit Kingsbury’s turbomachinery bearing services page.

Contact Kingsbury

Resources

The Effect of Lubricant Supply Temperature on Thrust Bearing Performance

The Effect of Lubricant Supply Temperature on Thrust Bearing Performance

Evaluation of a High Speed, Light Load Phenomenon in Tilting-Pad Thrust Bearings

Evaluation of a High Speed, Light Load Phenomenon in Tilting-Pad Thrust Bearings